Renegade 5×8

The Renegade 5X8 is one of the largest and most capable CNC system that we build. Similar to the Renegade 5X10, it is built for maximum speed and capacity. While most of our customers order the complete package with the vertical workstation and the turning workstation, you can customize the build by ordering only the workstations and accessories you need. The table can be set up in a variety of configurations and can be changed at any time.

Packages Starting at $49,500

Purchase what you need - upgrade whenever you want to!

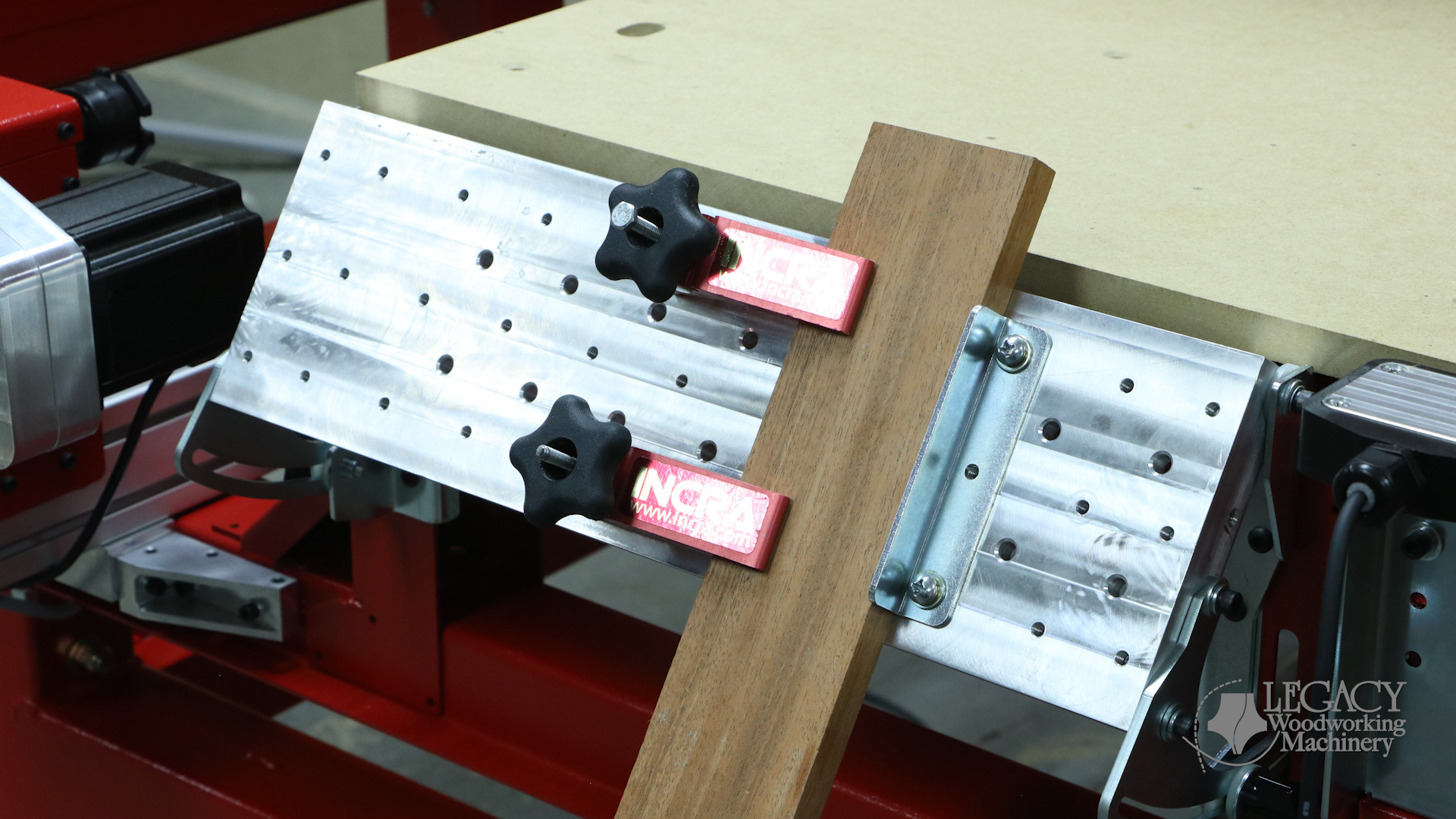

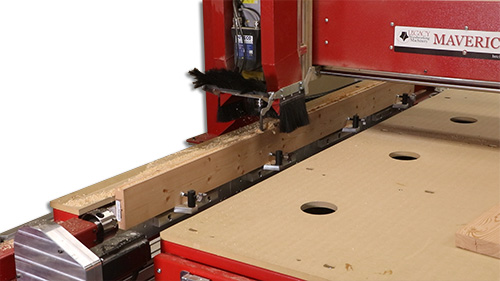

Shown with the optional Auto Tool Change Spindle, Vacuum Table System, Vertical Workstation, and Turning Workstation.

The Renegade 5×8 includes the standard 3-Axis workstation found on all woodworking CNC machines with a work area of 62″ x 96″. With a fully welded frame and feed rates up to 1,800 ipm, the Renegade 5×8 is designed for speed. In addition, it has a feature not found on other woodworking CNC machines… an open bay that greatly increases the machining capacity.

The Renegade 5×8 includes the standard 3-Axis workstation found on all woodworking CNC machines with a work area of 62″ x 96″. With a fully welded frame and feed rates up to 1,800 ipm, the Renegade 5×8 is designed for speed. In addition, it has a feature not found on other woodworking CNC machines… an open bay that greatly increases the machining capacity.