The Core System

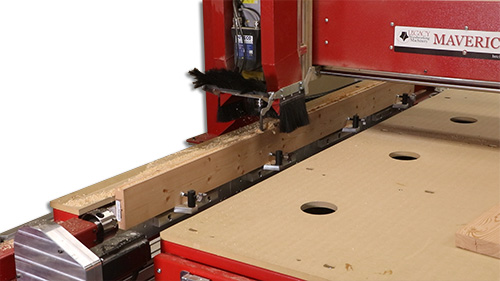

The Maverick 4×8 includes the standard 3-Axis workstation found on all woodworking CNC machines with a work area of 50″ x 98″. With a fully welded frame and feed rates up to 1,800 ipm, the Maverick 4×8 is designed for speed. In addition, it has a feature not found on other woodworking CNC machines… an open bay that greatly increases the machining capacity.

The Maverick 4×8 includes the standard 3-Axis workstation found on all woodworking CNC machines with a work area of 50″ x 98″. With a fully welded frame and feed rates up to 1,800 ipm, the Maverick 4×8 is designed for speed. In addition, it has a feature not found on other woodworking CNC machines… an open bay that greatly increases the machining capacity.

The Maverick 4×8 frame has an open bay that allows you to machine large components that will not fit on a standard 3-Axis table found on other CNC machines greatly expanding the capacity of the CNC.

Legacy’s Smart Tool system is more than a zeroing plate. It allows you to program files that work similar to an Auto Tool Change system. All of the toolpaths are saved to a single file and each cutting tool is set to the Z Zero plane as run the program.

When combined with the Auto Tool Change spindle, the Smart Topol can be used in one of two methods. The first is to simply enable the Smart Tool system when you run a program to touch off each bit as soon as it is picked up, setting the Z Zero plane on the fly. The second is to set up a tool length library and the Z Zero plane will be set by the software as you pick up the tool. One method is for simplicity when machining custom parts, while the second method is best for production.

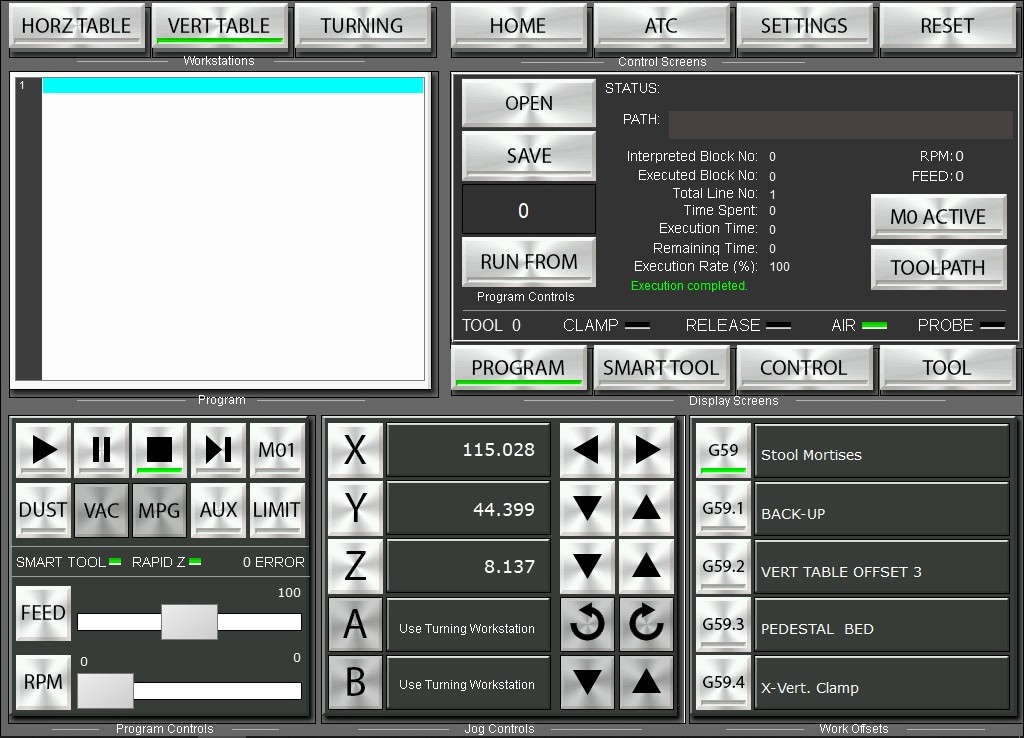

Legacy’s CNC controller was designed specifically for Legacy’s woodworking CNC systems with features not found on any other CNC. It is three CNC controllers, controlled by a single interface. Each of the three workstations – Horizontal, Vertical, and Turning are controlled independantly

The best option for increasing production speeds and automating the process. The Maverick 4X8 Auto Tool Change systems include the 6hp air cooled auto tool change spindle, 7 automated tool positions, and a set of ER32 collets. The Maverick 4X8 with Auto Tool Change will automatically change tools from the 7 tool clips plus will run programs with up to 12 cutting tools. When the program calls for a cutting tool that is not in one of the 7 automatic tool change positions, the program will move to the manual tool change position and prompt you to insert the requested tool, touch off the Smart Tool pad to set the Z Zero plane and then continue the program. This system also allows you to use the most efficient method by setting up a tool length library to automatically adjust the Z-Axis as the cutting tool is used.

Legacy’s sheet processing system is the optimal method for cabinet making and any type of sheet processing. It includes four independent regenerative blowers that are built into the frame of the CNC, vacuum and spoil boards, and an automated pin locating system. The Sheet Processing System does not lock you into sheet processing only. The 4X8 tables are divided into 4 2X4 zones allowing you to quickly change from a sheet processing table to a T-Slot clamping table on one of more sections. You can quickly change from processing 4×8 sheets to a part processing system with the optional turning workstation, vertical workstation, and T-Slot table all available at the same time.

Legacy’s Turning Workstation is more versatile than any other CNC turning system in its class. You can turn, carve, and machine parts mounted between centers. When combined with Legacy’s CCAM Pro software, you can quickly convert a basic 2D drawing into a turning program without modeling or sophisticated programming processes. Quickly add turned or indexed details. Legacy’s CNC controller allows you to turn non-symmetrical parts i.e. a Queen Ann leg or elliptical spindle. Legacy’s exclusive adjustable turning bed and Conversational CAM software allows you to program tapered square or round turnings up to 30 times faster than the standard 4-Axis CNC.

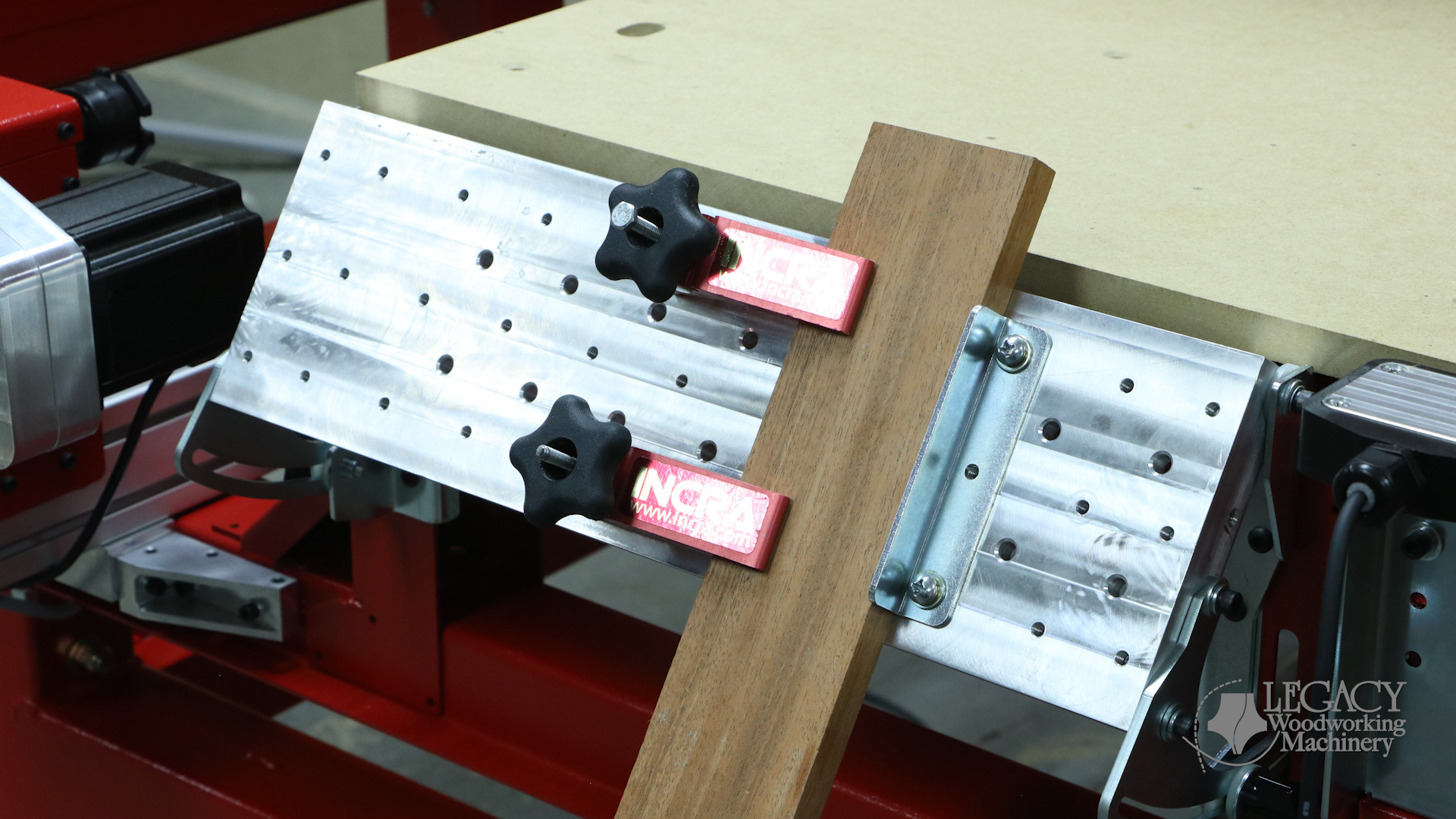

The Vertical Workstations allow you to machine on the ends and edges of your parts. The Y-Axis Vertical Workstation allows you to set the vertical table on angles between 0 and 90 degrees. This feature allows you to machine precision joinery including mortises, tenons, finger joints, dovetail joints, castle joints, and much more. By setting both the table and fence on an angle you can machine compound angle joinery.

This system mounts inside of the open bay allowing you to machine on the edges of long components.

See the 4X8 in Action!

Horizontal Workstation

Work Area – 50” X 98”

ATC Spindle

Auto Tool Change

Horsepower – 6.0 Hp 4.5kW

RPM Range – 6,000 – 24,000

Tool Holders – 7

Tool Holder Type ISO30 / ER32 Collet

Turning Workstation

Length – 79”

Swing Diameter – 10”

Bed Adjustment Angle – 0 – 3.9 Degrees

Bed Adjustment Method – Manual

Vertical Workstation (Y-Axis Mount)

Work Area – 11” X 28” X 44”

Table Angle Adjustment: 0 – 90 Degrees

Vertical Workstation (X-Axis Mount)

Work Area – 2” X 96” X 10”

Vacuum Table System

Zones – 4

Control – CNC Controller

Dimensions

Footprint: 147” X 76” X 72.5”

Weight: 2,400 Lbs

Electrical Requirements

Voltage: 220

Amperage: 50

Phase: Single

Includes: Controller, keyboard & mouse, 3-workstations,

Spindle, Dust manifold, Tooling, Smart Tool,

Fixtures, Maintenance supplies,

training, support,

Spindle: ATC, MTC

Vacuum Table

Mobility Kit

Conversational CAM

Take Advantage of

Legacy’s Special Financing

Available for a limited time